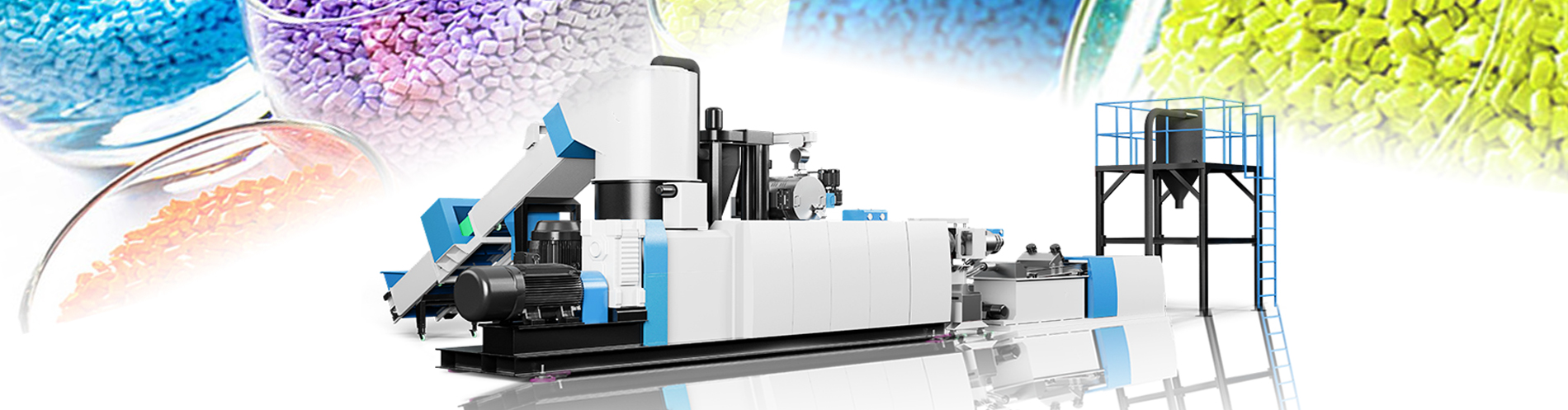

In the plastic recycling industry, choosing the right pelletizing system is the key to achieving efficient and sustainable production. Plastic pellet recycling systems can reuse plastic waste and convert plastic waste into usable clean raw materials. Through pelletizing, plastic manufacturers can reduce waste and convert waste plastics into high-quality materials that can be used in the manufacturing process, thereby achieving their green initiatives.

Quickly converts plastic waste into high-quality granules

Integrates seamlessly into existing production lines

By minimizing energy consumption and maximizing material recovery

Producing premium recycled materials that meet industry standards

Flexibility to handle various types of plastic waste

more sustainable recycling process and reduce waste

To choose a reliable manufacturer of plastic recycling machines, we are the right choice. We are committed to providing high quality washing or pelletizing lines that meet the highest industry standards and help organizations efficiently process and wash plastic waste.

With our advanced technology, you can maximize productivity while maintaining consistently high quality results. If you're ready to improve your plastics recycling process with our modern recycling machines, please to contact us.

We Crafted an awesome design library matter you're buildi business presentation websit or a complex web application our design blocks can easily.

We Crafted an awesome design library matter you're buildi business presentation websit or a complex web application our design blocks can easily.

We Crafted an awesome design library matter you're buildi business presentation websit or a complex web application our design blocks can easily.

Waste plastics are sorted, cleaned, and crushed to remove impurities and moisture. After the plastic is fed into the extruder:

Heating:

A heating process is carried out to melt the plastic and turn it into a viscous molten state.

Stretching:

The molten plastic is then forced through a die, which shapes it into long, continuous strands or filaments. The mold is designed to produce a specific shape and size extrudate.

Cooling:

This is usually accomplished using either a water bath or an air cooling system. In a water bath, the wire passes through a water tank, which cools and hardens rapidly.

Pelletizing:

After cooling, the pelletizer is equipped with rotating blades or cutters, and the cured plastic strip is cut into small, uniform pellets.

By converting waste plastics into reusable pellets, these machines contribute to the circular economy, extending the life cycle of plastics and minimizing their disposal in landfills.

By processing and reusing plastic waste, companies can reduce material costs, increase sustainability, and potentially open up new revenue streams through the sale of recycled plastics.