Video

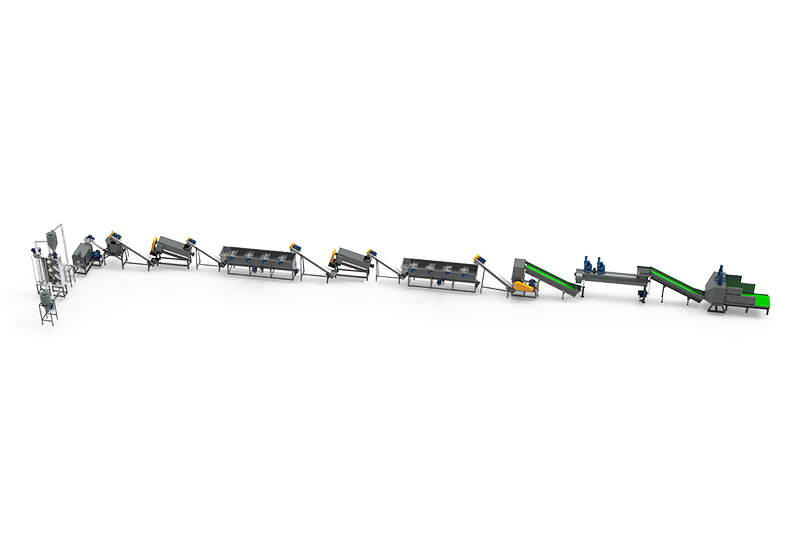

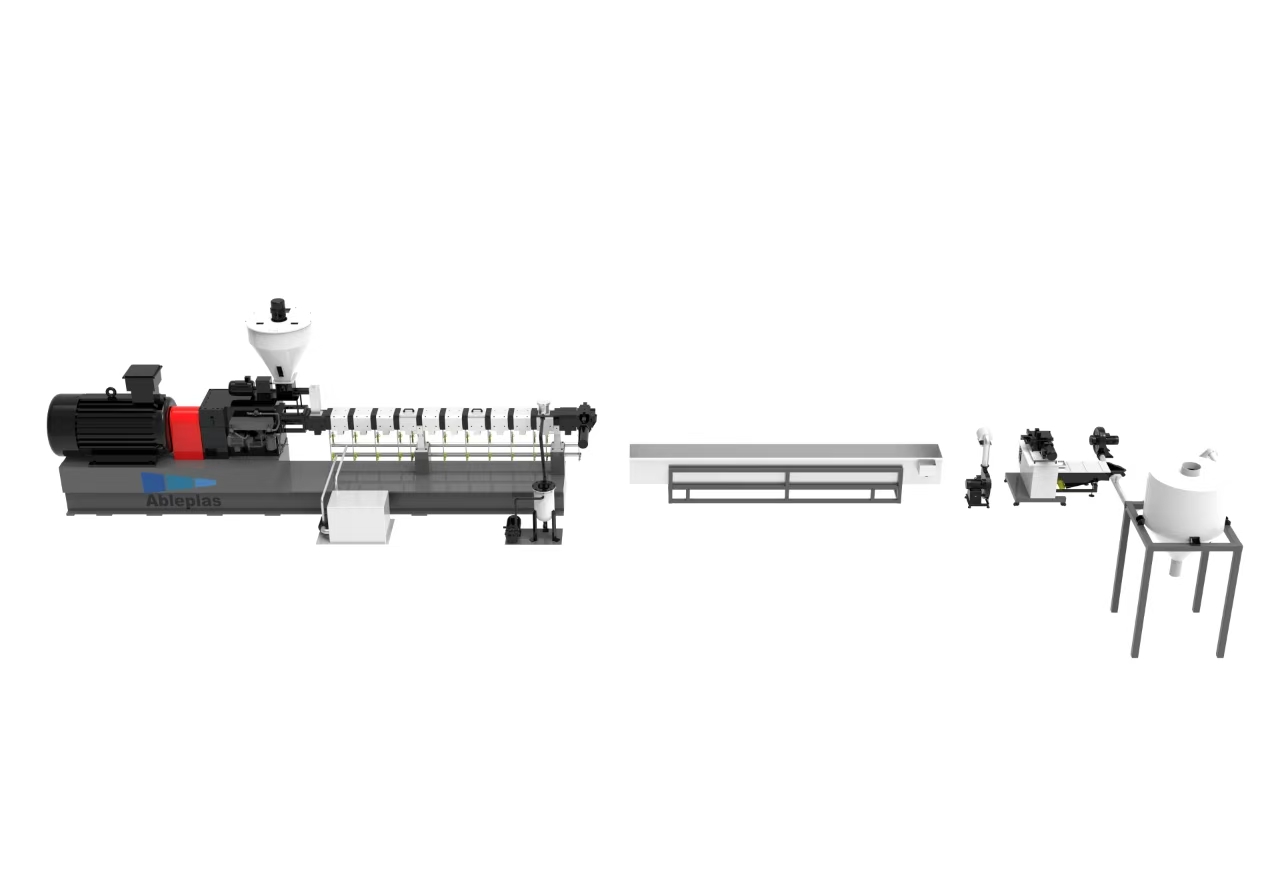

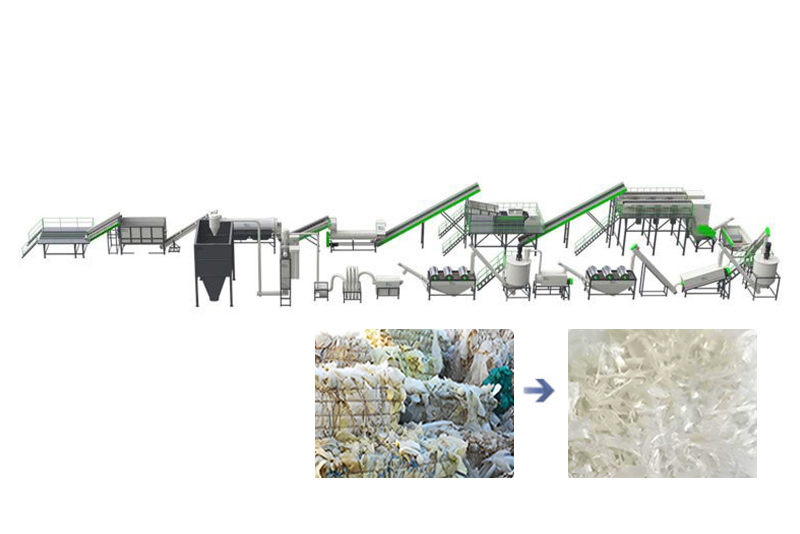

Pet Bottle Washing Recycling Line Detailed Image

Machine Parameters

Workflow

Production Lines Flow Chart

Feeder

Function:

Automatically convey PET bottles to the crusher to form a continuous production process and reduce manual intervention.

Design features:

Frequency control: The conveying speed can be flexibly adjusted according to the running speed of the production line to ensure uniform bottle flow.

Sturdy and durable: The conveyor belt is made of non-slip material to adapt to PET bottles of different sizes and weights.

Unpacking machine

Function:

Automatically open the compressed package of PET bottles and disperse the bottles for subsequent crushing and cleaning.

Design features:

Efficient unpacking: adapt to bottle packages with different packing densities to ensure the complete release of bottles.

Mechanized operation: avoid the inefficiency and safety hazards caused by manual unpacking.

Crusher

Function:

Crush PET bottles into small sizes (usually 12-18mm) for cleaning and subsequent processing.

Design features:

High-strength blade: A wear-resistant alloy blade is used to quickly and efficiently crush PET bottles of various thicknesses.

Screen design: The size of the crushed particles is controlled by the adjustable screen size to ensure uniformity.

Label remover

Function:

Use air suction and blade friction to remove plastic labels from bottles, including PVC labels, OPP labels, and other types of labels.

Design features:

Efficient separation: The label removal rate is as high as 98%, reducing the burden for subsequent cleaning.

Flexible design: no damage to the bottle, suitable for all types of PET bottles.

High-speed friction and floating cleaning machine

Function:

Deeply clean the crushed PET bottle flakes and separate metal, sand gravel, and other impurities.

Design features:

Multi-function cleaning: Combining high-speed friction and flotation cleaning technology to ensure high cleanliness of bottle flakes.

Automatic impurity removal: Set up a device to automatically remove floating objects and sediments to keep the cleaning water clean.

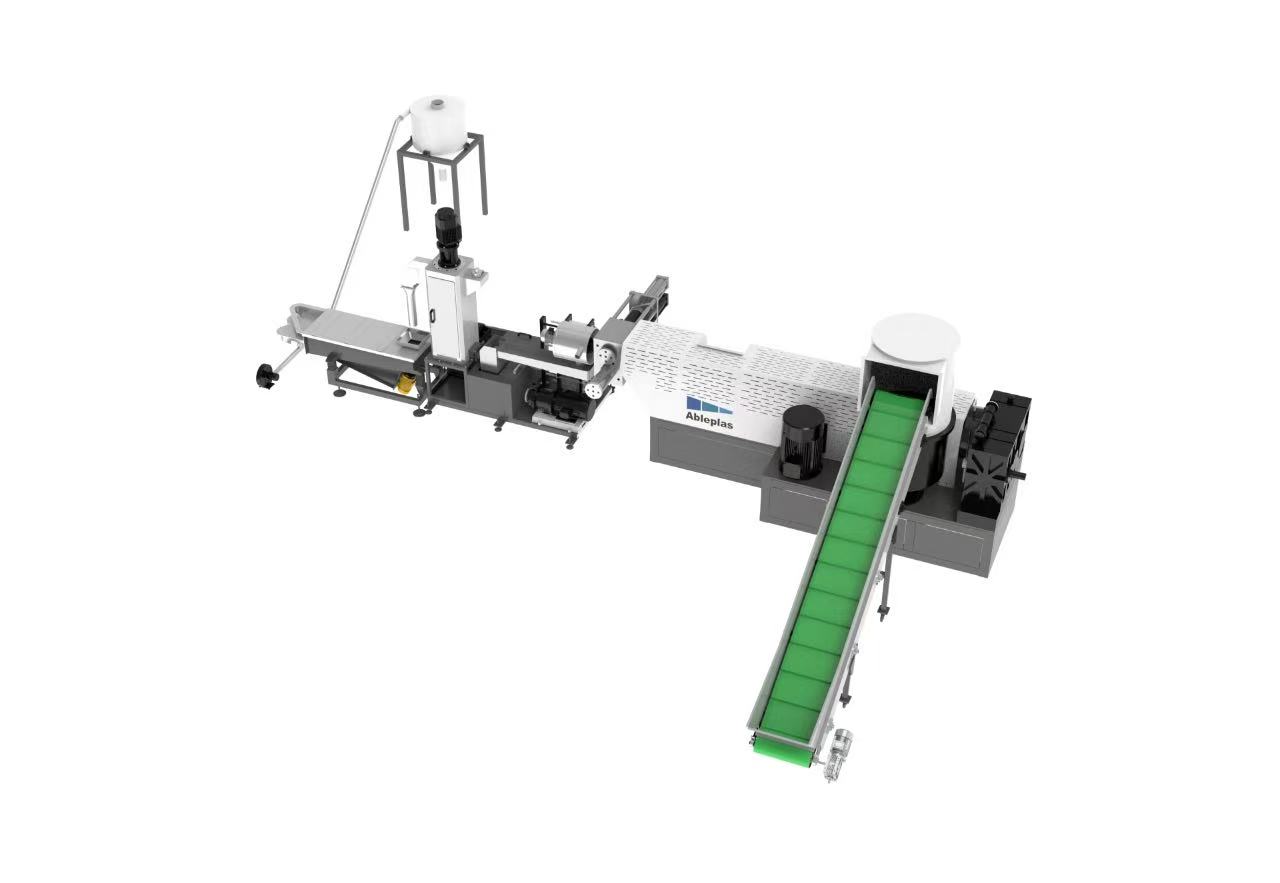

Dehydrator

Function:

Use high-speed rotation to remove moisture from the surface of PET bottle flakes, with a dehydration efficiency of more than 95%.

Design features:

High-speed centrifugation: The centrifugal force is used to completely separate the moisture on the bottle flakes, significantly reducing the subsequent drying time and energy consumption.

Automatic drainage: The bottom drainage system efficiently drains the separated moisture to keep the equipment clean and tidy.

Why Chose Us?

1. Reliable parts and supplier to ensure the quality

2. With more than 15years comprehensive experience, Highly skilled artisan together with modern processing methods ensure that ABLE has stable and high performance products.

3. Specially designed structure ensure the quality ,steady ,long life ,performance

4. Many leading companies in different industries have cooperated with us ,such as shengqili group(listed company) ,ALBIS PLASTIC GMBW ,TRUPER group mexico,Colormax group ,Green recycle Lebanon .

5. Rapid-response within 24hours

6. 100% raw material from ISO certified factory

7. 18 Months warranty

8. Engineers at your service anytime .

9. One -step purchasing supplier

Reviews

There are no reviews yet.