Video

Detailed Image

Machine Parameters

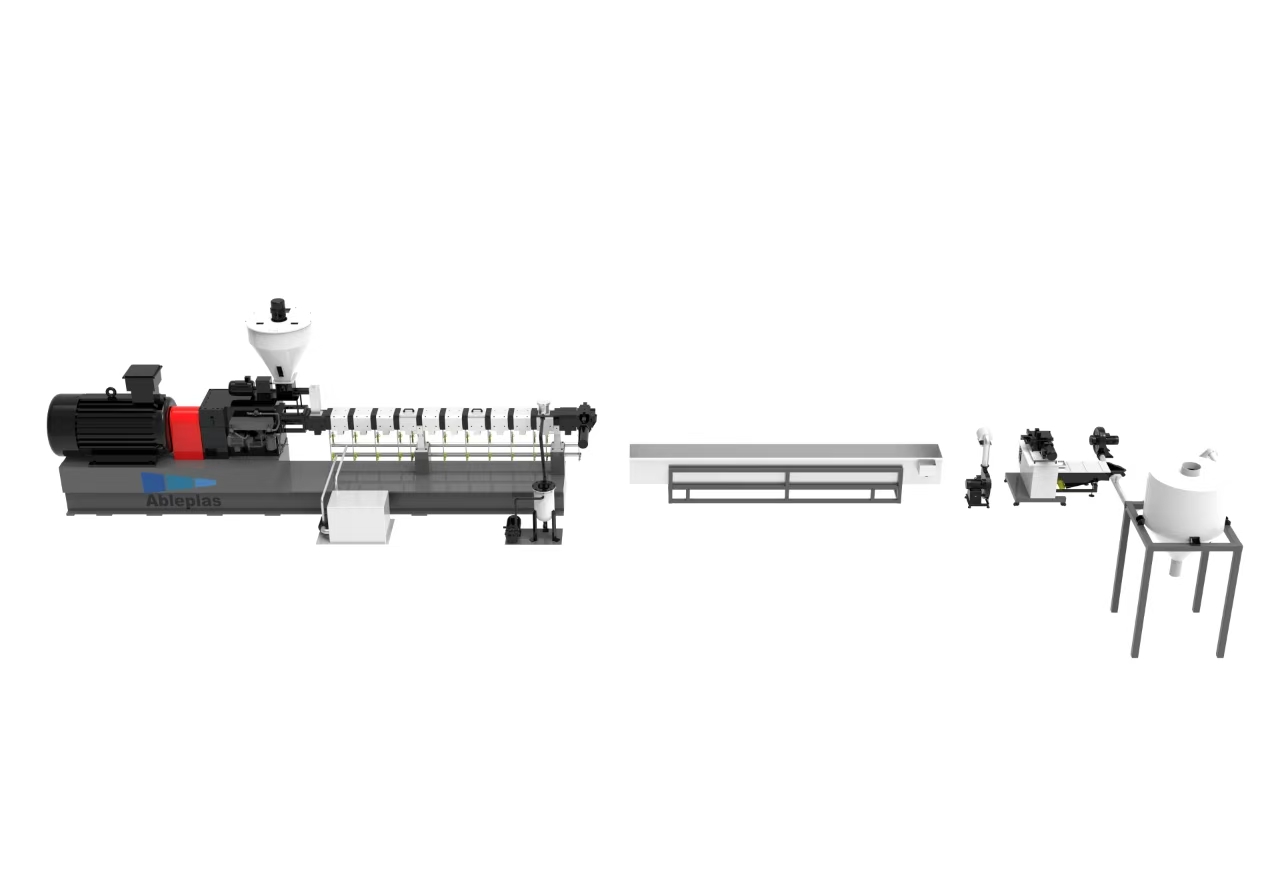

Process flow

Features

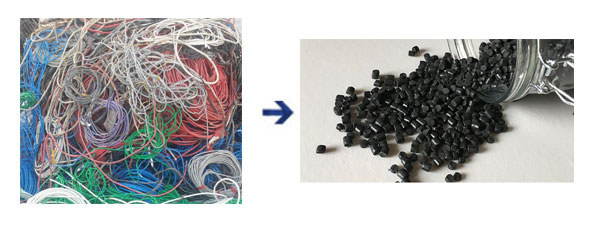

1. This plastic recycling pelletizing line is specially used for PVC soft material/flake recycling granulation.

2. Suitable for PVC cable, PVC pipe, PVC film, and other plastic granulation.

3. Forced feeding machinery, presses the flakes into the extruder so that the flakes can be easily fed into the screw barrel of a single extruder.

4. This plastic recycling pelletizing line is low power consumption, good granulation effect, and high output.

| Plastic Recycling Pelletizing Line | ||||

| Model | SJ90 | SJ100 | SJ120 | SJ150 |

| Extruder screw diameter | 90 | 100 | 120 | 150 |

| The main motor of the compacting machine(kw) | 37 | 55 | 75 | 90 |

| Production capacity(kg/h) | 100-150 | 200-300 | 300-400 | 500-600 |

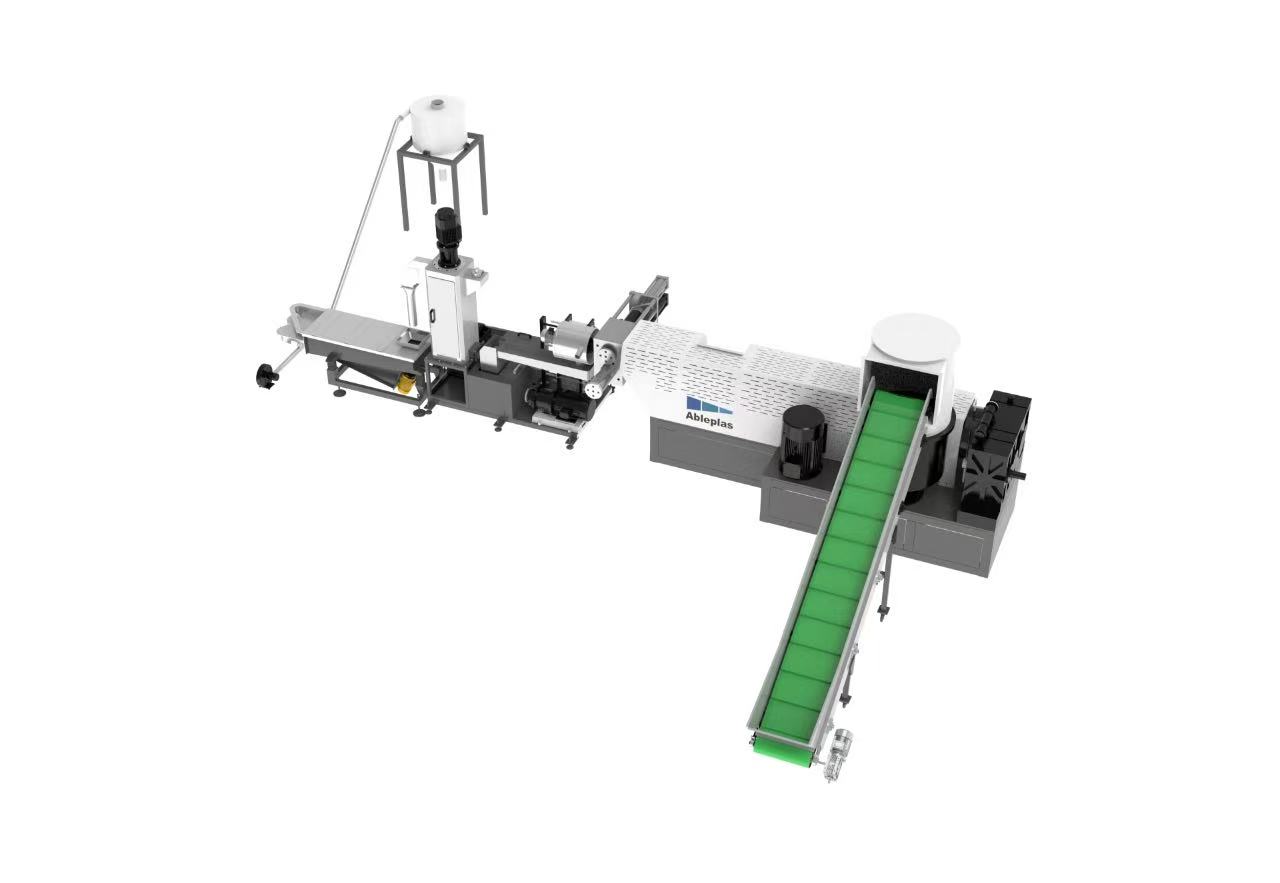

Production Lines Flow Chart

Screw feeding

Core functions:

Press bulk or loose PVC powder, granules, or mixed materials into the extruder feed port by mechanical force.

Features:

Pressure control: adjust the feeding pressure to match the feed speed with the extruder screw speed.

Reduce waste: avoid feed port blockage and raw material backflow, and ensure efficient use of materials.

Screw extruder

Core functions:

Heat, mix, and plasticize PVC raw materials into a uniform molten state, and extrude them into the desired form through the die head.

Features:

Precise temperature control: The multi-stage heating system controls the temperature of the melt in different zones to avoid high-temperature decomposition of PVC.

High torque drive: Ensures stable output and is suitable for high-viscosity materials.

Pelletizing system

Core functions:

Quickly cut the melt or strip material extruded from the die head into uniform particles.

Features:

High-precision cutting: The cutter speed is adjusted synchronously with the material flow rate to ensure uniform particles.

Anti-adhesion design: The particles are immediately cooled or put into water after cutting to prevent surface adhesion.

Water tank

Core functions:

Provide rapid cooling for high-temperature particles or strips to harden and shape them.

Features:

High cooling efficiency: Utilize the circulating water system to maintain constant water temperature, and control the cooling time by designing the length and depth of the water tank.

Automatic impurity removal: It is equipped with a filter and sewage system to remove impurities or fine particles from the cooling water.

Air Dryer

Core functions:

Remove residual moisture from the surface of particles through high-speed airflow and centrifugal force.

Features:

Efficient drying: Use centrifugal fans to generate high-speed airflow to evaporate the moisture on the particles quickly.

Centrifugal separation: The particles are separated from the moisture through the rotating centrifugal structure, further improving the drying effect.

Why Chose Us?

1. Reliable parts and supplier to ensure the quality

2. With more than 15years comprehensive experience, Highly skilled artisan together with modern processing methods ensure that ABLE has stable and high performance products.

3. Specially designed structure ensure the quality ,steady ,long life ,performance

4. Many leading companies in different industries have cooperated with us ,such as shengqili group(listed company) ,ALBIS PLASTIC GMBW ,TRUPER group mexico,Colormax group ,Green recycle Lebanon .

5. Rapid-response within 24hours

6. 100% raw material from ISO certified factory

7. 18 Months warranty

8. Engineers at your service anytime .

9. One -step purchasing supplier

Reviews

There are no reviews yet.